Sponsored by BSI, this module will explore PAS 2080 and how the standard’s requirements enable professionals to embed carbon management excellence throughout the built environment supply chain.

Reducing greenhouse gas emissions is one of society’s most urgent challenges. For the built environment, this involves significant, interconnected obstacles. On top of its sustainability aspirations, the industry faces rising material costs, rapid population growth, skills shortages, ageing infrastructure and increasingly limited access to finance.

But there is much to be optimistic about. Fast-moving innovations, including low carbon materials, smart building technology and generative design platforms, are helping to accelerate progress towards a more sustainable world.

As no single agency is directly responsible for reducing the industry’s carbon emissions, a framework for collaboration and a rigorous global standard that ensures quality, consistency and clarity across the value chain will be crucial to meeting the industry’s climate targets.

PAS 2080:2023 Carbon management in infrastructure sets out provisions around clear data that allow built environment professionals to track and report whole-life carbon emissions on major infrastructure and building projects. In this module, we will explore how organisations can embed carbon management excellence into their value chain using PAS 2080 as the framework – unlocking the ability to harness breakthrough technologies, methods and materials and accelerating the mission to net zero.

Learning objectives

- Awareness of how innovations are breaking new ground in carbon reduction.

- Knowledge of independent verification and digital solutions that are uniting the supply chain.

- Exploring examples of how PAS 2080 has benefited organisations, from emission reduction and enhanced collaboration to cost savings.

Driving change

By 2050, an estimated 68% of the world’s population will live in urban areas. Rapid urbanisation, population growth and greener lifestyles have the potential to encourage the built environment to adopt new business models, technologies and infrastructures. Pressure is rising for governments to introduce and enforce decarbonisation measures through regulation, grants and incentives, in addition to enabling conditions for private finance solutions.

A new generation of citizens are entering the workforce and expect sustainability to be a top priority. This will no doubt have implications for organisational transparency and structure. In response to skills shortages and recognition that governments alone cannot solve the climate crisis, responsibility for net zero could be shared more widely among researchers, NGOs and corporations.

Alarming declines in biodiversity worldwide have raised fears that the natural ecosystems we rely upon to survive could collapse – intensified by the built environment’s processes and use of materials. According to the Construction Products Association (CPA), construction and demolition in the UK alone produced 68 million tonnes of waste in 2018 – 92% of which was recovered.

The construction industry is expected to shift from the take-make-waste model towards renovating existing assets with innovative, low-impact materials. The Ellen MacArthur Foundation estimates that a circular economy could reduce global CO2 emissions from building materials by 38% in 2050.

Organisations seeking lucrative contracts within the built environment are under increased pressure to demonstrate digital innovation, process excellence and leading sustainability strategies. However, without access to high-quality and reliable data, they may be unable to report effectively on carbon emissions or view the entire value chain.

When unwanted consequences of a fragmented supply chain occur, it can discourage communication, allowing inertia to set in – since no one entity is responsible for carbon management. The challenge that the industry faces is how best to unite disparate stakeholders on buildings and infrastructure projects.

This is where PAS 2080, the world’s first standard for managing carbon in buildings and infrastructure, can bring tangible value.

Introducing PAS 2080

PAS 2080 is the leading standard for carbon management solutions in buildings and infrastructure development. Independent verification supports the industry by assessing your delivery of projects to PAS 2080 requirements, your measurement and monitoring of carbon against project delivery, the management of your supply chain, and your role within it.

Alongside managing and reducing the carbon emissions of your projects, the PAS 2080 certificate of conformity programme demonstrates a commitment to the future of sustainable infrastructure. The standard applies to new projects or programmes of work, as well as the management or retrofit of existing assets and networks. This means those working on new buildings or infrastructure projects can consider the carbon footprint throughout their entire lifecycle, from design and construction through to operation and end-of-life decommissioning.

By giving every stakeholder clarity from the outset around carbon targets and how best to achieve them, PAS 2080’s provisions for transparency and clear communication allow built environment professionals to proceed with confidence when:

- Planning for the present as you devise and enact low-carbon solutions

- Preparing for the future by proposing ambitious goals with innovative ideas.

The standard was revised with PAS 2080:2023, to incorporate a broader scope of activities that affect carbon management, including an expanded scope beyond infrastructure, requirements specific to the procurement and decision-making stage, the integration of broader factors and an emphasis on leadership, collaboration and governance structure across the value chain.

Standards and independent verification can help organisations seeking to adopt net-zero principles because they embed sustainability into the fabric of the business at every stage and enable professionals to be better equipped to share best practices.

How does PAS 2080 encourage effective collaboration on carbon management?

- Sets clear targets for carbon reduction

- Defines roles and responsibilities across the value chain

- Provides a common framework for data sharing, process alignment and transparency

- Establishes easy-to-follow metrics and KPIs

- Integrates carbon reduction into project decisions, including design.

Carbon and costs

Limiting expenditure is a significant ongoing consideration for most stakeholders across the built environment, and carbon reduction initiatives can often result in cost savings throughout the project’s lifecycle.

As the built environment looks to move away from the take-make-waste model, many forward-thinking initiatives are already accelerating the industry’s vision of being a low carbon leader. These initiatives illustrate why embracing a contextual model – one in which project benefits are integrated with positive outcomes for local communities and wildlife habitats – will be crucial to our progress towards a more sustainable future.

Examples of efficiencies achieved through focusing on carbon reduction include:

Heysham to M6 road project, Lancashire (Costain and Tarmac)

- A 25% reduction was achieved in aggregate tonnage and ready-mix concrete, along with 21% CO2e savings.

- Close collaboration two years before the start of works enabled a deeper understanding of the companies’ respective operations and how to integrate them effectively.

- Strategic decisions made prior to construction, from quarrying to vehicle routes, helped optimise processes and minimise waste.

M5 Junction 27-28 resurfacing scheme, Willand (Skanska)

- The original projected cost of £4.5m was halved, and the carbon footprint was reduced by 23%.

- Skanska found cost and carbon reductions by optimising its resources. It planned truck movements to allow for continuous asphalt production.

- A hot-box technique kept the equipment at an optimal temperature when batching asphalt.

Thameslink signal structures project (Balfour Beatty Rail)

- A 60% reduction in carbon footprint and projected costs was achieved, compared with the original proposal.

- By re-evaluating and modifying the design of new cantilever structures and using existing gantry structures as part of that design, Balfour Beatty Rail found considerable reductions in waste, cost and material usage.

- There was no excavated soil to be removed from the site, and thanks to the modified proposal, a parapet wall no longer needed to be demolished.

Innovation in action

To drive innovation while securing trust in the built environment, industry professionals must consider holistic strategies that emphasise process excellence and collaboration with the right partners as much as procuring the latest tech and low carbon materials.

Effective innovation is the process of drawing from experience to enter the unknown. This section will equip the reader with real-life examples of innovation in action. Using this insight into emerging solutions, organisations can confidently shift boundaries and propel the industry forward.

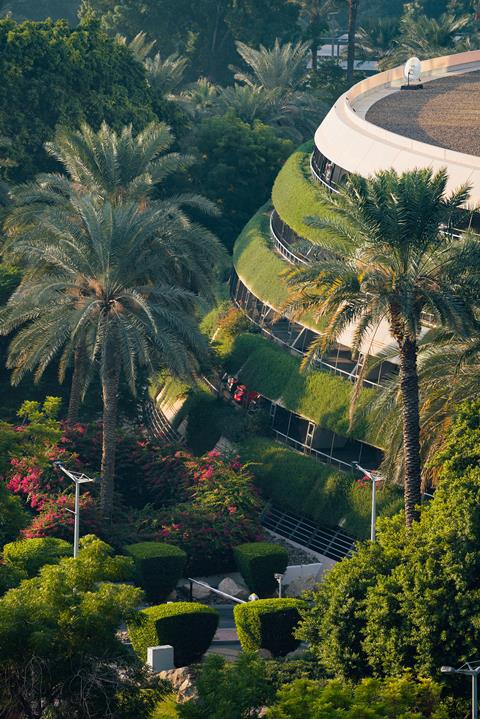

The following built environment breakthroughs showcase industry leaders integrating clever design and low carbon innovations into their business practices, limiting material usage and reducing emissions across the whole value chain.

GenZero schools

A platform solution for manufacture and assembly made using a standard kit of parts that was designed digitally and to be rolled out at scale, GenZero was the UK’s first ultra-low carbon standard for schools, using UK-sourced timber as the primary material and reducing typical timber use for similar buildings by 35%. The solution demonstrates next-generation design and digitalisation and how organisations can optimise material usage and design efficiency throughout the construction lifecycle.

Shrewsbury Flaxmill Maltings

Bringing together architects, surveyors, brick specialists, builders, carpenters, ecologists, engineers, ironworkers, roofers and scaffolders, the restoration of Shrewsbury Flaxmill Maltings features a ground-source heat pump (estimated to reduce space heating emissions by 46%) and an integrated bat roost.

Retrofitting solutions are helping to decarbonise existing building blocks and reduce the sector’s reliance on new construction. Innovations such as heat-loss-reducing smart air bricks, mechanical ventilation with heat recovery (MVHR), heat pumps (ground, air or water source) and AI-powered retrofit assessments are revolutionising the industry.

Hamerbrooklyn Pavilion

Using sensor technology and internet of things (IoT) interfaces, the Hammerbrooklyn Pavilion in Hamburg collects data on temperature, oxygen and occupancy to optimise energy use. It was built from upcycled materials, including boardwalk planks salvaged from Hurricane Sandy in 2012 and a steel frame repurposed from the US Pavilion at Expo Milan 2015.

AI-powered platforms can help to continuously track performance and drive carbon reductions in smart buildings with consumption-monitoring and occupancy-responsive services.

Hyperion Robotics

This concrete construction solution uses low carbon concrete – made from mining tailings, ashes and slags – to 3D print structures such as foundations, water tanks, trenches and buildings. A recent pilot project for Iberdrola and Peikko building pillars for electric substations resulted in a 75% reduction in material use and a 60% drop in eCO2.

These innovative natural or recycled alternatives can reduce industry costs and dependence on virgin raw materials. From carbon-negative lightweight aggregate (OSTO), cementless concrete (Earth Friendly Concrete), panel boards made from waste materials, and the rise of biomaterials such as hemp, mycelium and timber, innovations in the sector are only growing.

��Ȧ the foundation

From legislative leaders to corporate influencers, the industry has the opportunity to encourage professionals to switch from defaulting on established methods to adopting cutting-edge technology. A crucial part of the solution will be for the built environment and its regulatory bodies to embrace a trusted framework that enables the sector to evaluate and optimise its sustainability efforts.

Harnessing the full range of sustainable design principles includes:

- A low-build future in which heat pumps, solar panels and insulation are routinely installed in new and retrofitted buildings.

- Optimising existing resources by reducing, reusing or omitting materials, aided by supply chain partners.

- Adopting digital innovations such as AI, machine learning, building information modelling (BIM), and digital twins to reduce lead times and optimise construction.

- Integrating biophilic design principles to preserve and highlight surrounding natural habitats, enhance wellbeing and promote biodiversity.

- Sourcing retrofit solutions for building envelopes and smart building systems that can withstand extreme weather events such as flooding and heatwaves.

- ��Ȧs, infrastructure and initiatives that foreground inclusive, community-minded living.

- Establishing trust in innovations.

The PAS 2080 advantage

Without an assurance framework that provides the confidence to adopt sustainable methods at speed and scale, organisations may find it difficult to stray from the tried and tested – even where the new methods have proven benefits.

This challenge is especially pressing for government agencies that consult with built environment leaders to shape guidance on safe construction methods and materials. Adopting an innovation-first approach can help us to construct a more sustainable built environment and is even more effective when supported by a harmonising standard that breeds trust across the value chain.

PAS 2080 gives built environment professionals a platform where innovation thrives because the governance structure empowers leadership teams to challenge existing standards and specifications whenever an opportunity arises to meet carbon targets.

The value of the PAS 2080 framework lies in enabling stakeholders across the value chain to agree on metrics, KPIs and incentives, minimising ambiguity. The standard offers a holistic carbon management structure with clear guidance on target setting, baselines, monitoring, reporting and continuous improvement. It also offers reductions in material and labour costs by clarifying roles and responsibilities, decision-making and procurement.

Final thoughts

A more framework-friendly context is already emerging when considering the broader industry environment. The EU is currently revising its Construction Products Regulation (CPR) to better encourage sustainability and innovation. The EU’s report on that process shows that the market appetite for a better built environment is not only gathering momentum but will also widen the global industry’s scope for activity with European partners.

As built environment organisations face soaring costs, it is equally important to plan for long-term resilience in the industry’s movement towards more sustainable practices. PAS 2080 can pave the way for the built environment to excel as a carbon-conscious industry.

Far from requiring a radical process overhaul from built environment professionals, the standard is there to help strengthen your existing compliance strategies. It aligns with the priorities outlined in the UK government’s Construction Playbook, which addresses some of the most urgent issues in the built environment.

Carbon management is a fragile process. It can take just one stakeholder in the value chain to renege on carbon targets for the whole project to miss its net zero ambitions. That is why all those involved in the construction process must encourage their network to take the leap and drive towards net zero.

Please fill out the form below to complete the module and receive your certificate:

No comments yet