Sponsored by Tobermore, this module explores the design considerations, applications and benefits of specifying segmental retaining walls in residential developments. Covering key aspects from initial planning through to construction, it highlights how solutions can address site-specific requirements

Retaining walls play a critical role in modern construction, helping to manage elevation changes, prevent soil erosion and create stable land formations by transforming steep terrains into usable spaces.

The concept of reinforced soil structures has existed for centuries, with ancient civilisations using stone and timber to stabilise slopes and build terraces. However, modern segmental retaining walls (SRWs) emerged in the late 20th century when engineers developed high-strength concrete blocks with interlocking features.

The introduction of geosynthetic reinforcements, such as geogrids, in the 1980s significantly advanced SRW technology, allowing for the construction of taller, more robust structures capable of withstanding increased loads. Over the years, SRWs have evolved with improvements in material strength, design methodologies and environmental considerations, making them a go-to solution for engineers and specifiers seeking efficiency and long-term durability.

This module is designed to support architects, housebuilders, engineers, local authorities and specifiers in selecting the correct retaining wall for their projects. Readers will gain a comprehensive understanding of SRWs, including their benefits, limitations, construction methods and relevant technical certifications to ensure informed decision-making in real-world applications.

Learning objectives

- Understand the principles of retaining wall design, including key factors such as site conditions, loading requirements and material selection.

- Gain insight into the benefits and applications of SRWs for residential developments, including their construction methodology, aesthetic versatility and structural performance.

- Knowledge of best practice for planning, design and installation, ensuring compliance with relevant standards.

Types of retaining walls

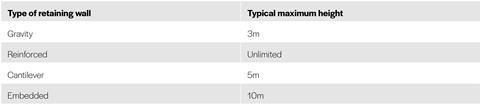

Choosing the right retaining wall is essential to ensuring stability, longevity and cost-effectiveness. The best solution depends on factors such as soil conditions, site constraints, loading requirements and overall project objectives. Below is an overview of the primary types of retaining walls, their construction methods, benefits and key considerations.

Gravity retaining walls

Gravity retaining walls rely on their substantial mass to counteract the lateral earth pressures the retained soil exerts. Constructed from materials such as stone, concrete or heavy masonry units, these walls are often designed with a slight backwards lean, known as a batter, to enhance stability.

They are particularly effective for lower-height applications due to their inherent stability and straightforward construction methods. However, as wall height increases, the base width must proportionally expand to maintain stability, which can consume valuable space and materials.

Reinforced soil retaining walls

Reinforced soil retaining walls integrate the wall’s mass with the reinforced soil’s strength to resist lateral earth pressures. This is achieved by embedding reinforcing elements, such as geogrids or geotextiles, into the soil behind the wall face, creating a composite mass that acts cohesively. Geogrid is a high-strength geosynthetic material that extends into the backfill.

This method allows for the construction of taller walls capable of supporting greater loads than traditional gravity walls. The flexibility in design and material selection makes them suitable for a wide range of applications, from highway embankments to commercial developments. However, installing reinforcement layers requires meticulous planning and execution to ensure structural integrity.

Cantilever retaining walls

Cantilever retaining walls are constructed from reinforced concrete and feature an internal stem connected to a base slab, forming an inverted T or L shape. This design efficiently transfers lateral earth pressures into vertical forces on the foundation. Cantilever walls are advantageous when space is limited, as they occupy less area than gravity walls. They are suitable for medium-height applications, typically up to 5m. However, they require precise engineering and construction practices, including substantial concrete footings below frost depth, to ensure durability and performance.

Embedded retaining walls

Embedded retaining walls, such as sheet pile walls or bored pile walls, are driven or cast deep into the ground to retain soil. They are particularly effective in soft soil conditions or tight spaces where traditional wall types are impractical. Sheet pile walls, made from materials such as steel or vinyl, are driven into the ground and are ideal for temporary or permanent structures requiring minimal space. Bored pile walls involve drilling and casting concrete piles in situ, providing robust support in challenging soil conditions. However, both types often necessitate specialised equipment and expertise, potentially increasing project costs.

Segmental retaining walls

SRWs are a subset of gravity retaining walls that use modular, interlocking concrete units to retain soil. These dry-stacked units rely on their mass and interlocking mechanisms for stability, making them a flexible and adaptable solution for various site conditions. They can function as gravity walls for lower heights or be reinforced with geosynthetics to construct taller structures, integrating principles from reinforced soil retaining walls.

The modular nature of SRWs allows for aesthetic versatility, with a range of colours, textures and finishes to complement project designs. They are commonly used in residential landscaping, commercial developments and infrastructure projects. Their dry-stack, mortar-free construction enables rapid installation, even in varying weather conditions, with skilled crews achieving approximately 40m2-50m2 daily.

Proper design and installation are crucial to ensure long-term performance, particularly in addressing drainage and soil characteristics. Compliance with standards such as BS EN 771-3:2011, which specifies requirements for aggregate concrete masonry units, is essential to ensure quality and durability.

In the subsequent section, we will delve deeper into the considerations of SRWs, providing a comprehensive understanding of the specification process at each design stage.

Concept design

In the concept design phase, it is essential to grasp the fundamentals of SRWs, assess preliminary costs and determine their applicability to specific projects. Although uncommon, engaging with manufacturers at this early stage can provide valuable insights into retention options, ensuring informed decisions as the project progresses.

While material costs for SRWs may appear higher initially than alternatives, the expedited construction timeline and reduced labour requirements often result in overall cost savings. Additionally, the potential to reuse on-site materials as backfill can further enhance economic efficiency. However, challenges such as market unfamiliarity can lead to design hesitancy or reluctance from clients and contractors. Moreover, SRWs often require specialised design input early on, necessitating collaboration with structural engineers to develop project-specific solutions.

Understanding these aspects during the concept design phase ensures that SRWs are appropriately considered and aligned with project goals and site-specific conditions.

Developed design

The developed design stage refines the technical specification and aesthetic details of SRWs. This phase ensures the solution integrates seamlessly with the project’s overall design, meeting structural and visual requirements.

Reviewing standard details and existing installations can provide a clearer understanding of how SRWs will perform in practice. Previous case studies can offer valuable insights into construction methods, material choices and design refinements that improve efficiency on site.

Detailed decisions regarding colour, texture and layout come into focus at this stage. While functionality remains the priority, the visual impact of retaining walls should not be overlooked – particularly in residential and public spaces.

For larger retaining walls, banding or patterning can break up the visual mass and enhance the design. Depending on the project’s intent, the use of colour variation can help the wall blend into the landscape or create a striking architectural feature.

With more detailed design work in progress, several factors need to be addressed at this stage:

- Co-ordination with other site elements – the retaining wall must integrate with adjacent structures, pathways, drainage systems and soft landscaping features.

- Structural and geotechnical input – where walls exceed certain heights or retain significant loads, early engagement with engineers helps refine the design to meet performance requirements.

- Construction detailing – the buildability of the chosen system should be carefully reviewed, including base preparation, drainage provisions and any reinforcement requirements.

By thoroughly addressing these elements at the developed design stage, project teams can refine their approach to ensure that the selected SRW system meets practical and aesthetic objectives.

Technical design

At the technical design stage, the focus shifts to the detailed engineering and construction methodology required to bring SRWs from concept to reality. This involves refining structural considerations, ensuring compliance with industry standards and co-ordinating the retaining wall design with other site elements such as steps, fencing and landscaping.

To ensure structural integrity, engineering consultants with expertise in retaining wall design can develop site-specific preliminary designs. These initial designs help determine the most appropriate construction method and are often sufficient for planning applications.

All SRWs should be manufactured in accordance with BS EN 771-3:2011 – Specification for masonry units, designed in accordance with BS 8006-1:2010+A1:2016 – Code of practice for strengthened/reinforced soils and other fills, and designed following BS EN 1997-1:2004 Eurocode 7: Geotechnical design (A1:2013). Ensuring adherence to these standards provides confidence in the system’s performance.

Geogrid reinforcement is the preferred approach for SRWs that are more than 1m in height or require additional stability. Key factors influencing the design of a geogrid-reinforced wall include wall height, soil conditions and the anticipated surcharge. The geogrid layers are placed between block courses at regular intervals, typically every four courses, and must be installed in the correct orientation to ensure optimal strength.

A concrete backfill approach can be used instead of geogrid reinforcement for sites where excavation space is limited or where minimising ground disturbance is critical. This involves filling the void behind the blocks with a no-fines concrete mix (concrete that doesn’t contain fine aggregates such as sand or crushed stone), forming a monolithic structure that resists lateral pressures.

A no-fines concrete backfill wall typically requires excavation of 40% of the overall wall height, compared with 70% for a geogrid-reinforced wall. This makes it a preferred choice in boundary-constrained sites or areas where excavation and soil removal would be costly.

In challenging environments where traditional retaining methods may not be feasible – such as steep slopes, restricted boundaries, or areas with existing structures – geopins and soil nail stabilisation systems can provide additional support. These systems involve the insertion of small-diameter pins or nails into the retained soil, reinforcing the ground and preventing movement.

Integrating these advanced solutions into the design allows SRWs to be successfully implemented even in complex site conditions.

Other considerations

It is essential to consider various factors that could influence the final implementation of the SRW system. These considerations include integrating fences, accommodating external curves, managing corners and planning for steps.

Fences

The integration of fences or railings with SRWs require careful planning, as these may require additional geogrid reinforcement. Failing to account for them early could necessitate extra work during construction, such as excavation of drainage aggregates, removal of backfill materials or additional geogrid cutting.

The design phase should determine the location and spacing of fence posts. Additionally, it is crucial to factor in the additional forces that certain fences, such as close-board fences, can exert on the wall. These fences create wind loads, requiring added reinforcement in the retaining wall.

It is advisable to avoid installing fences directly into the coping of the wall. Instead, consider using cantilever fencing to prevent the creation of a ledge. If in doubt, seek guidance from a specialist or manufacturer to ensure proper design and installation.

External curves

Certain segmental retaining wall blocks, especially those with a trapezoidal shape, make achieving internal and external curves relatively simple. A smooth curve can be formed without additional complexity by rotating the blocks to the required angle. However, it is beneficial to review the site plan at this stage and remove any tight curves, as they may limit the overall height of the wall.

The minimum radius for the curve must be defined, which should be established for the base course. If the radius is not considered from the outset, it could restrict the height of the wall and introduce complications later in the build.

For effective geogrid placement in curved walls, ensure that the geogrid material follows the curve 25mm behind the face of the blocks. Depending on the width and degree of the curve, the geogrid may need to be trimmed for proper fit.

Corners

Corners, whether internal or external, are a common feature of many SRW designs. A 90º internal or external corner is typically straightforward to construct. It is recommended to start construction from the corner and work outward for internal corners. The rear nibs on the base course of blocks should be removed to accommodate the corner design.

For external corners, begin at the corner, using special corner blocks that feature an additional decorative face. These corner blocks are typically supplied in pairs, making it easy to alternate between left- and right-facing blocks as you build.

Consider securing the corner blocks with construction adhesive to enhance the bond strength at the corner. This step ensures the corner remains stable throughout the structure’s lifespan.

Steps

Retaining walls often need to work with steps, especially on sloped sites. SRWs are compatible with standard step units, and individual blocks can be easily cut to create the required risers.

When designing steps, it is essential to identify any load-bearing fixtures, such as handrails, early in the planning phase. If handrails or similar fixtures are to be installed, the block voids in the relevant sections of the wall should be filled with C20/25 concrete to provide secure anchorage for the fixings. This ensures that the step structure can safely bear the load from these fixtures.

Step designs should also adhere to local building regulations, and designers should refer to the relevant standards to ensure safety and compliance.

Challenging sites

Specific site conditions and constraints can pose significant challenges when implementing SRWs.

Sites with highly acidic or sulphate-rich soils present additional challenges for retaining wall systems. Sulphates can react with concrete, causing rapid degradation of the material. For sites with high sulphate content – such as those with DS-5 level sulphates – many traditional retaining wall systems are unsuitable due to the corrosive effects of the soil on concrete.

However, SRWs can be a suitable solution in such conditions. Using aggregate and backfill in SRWs provides a protective barrier, preventing the sulphate-rich soil from directly interacting with the concrete and reducing the risk of damage. Additionally, foundations can be constructed with compacted granular fill, further safeguarding the system from the effects of aggressive soils.

Construction

As we move into the construction phase, indemnification is a priority. A geotechnical engineer can offer fully indemnified designs if the engineer is not prepared to take responsibility or the client requires extra assurance. These designs go beyond the preliminary scope of work and typically include:

- Ground conditions and design parameters

- Full information on the backfill, surcharge loads and crest/toe slopes

- Groundwater and drainage details

- Methods of analysis

- Specific design risks and suggested remediations

- A clear, detailed breakdown of each wall.

The following materials are typically required for the construction of SRWs in residential settings:

- Foundation:

- Type 1 granular compacted aggregate

- C20/25 concrete

- Drainage aggregate:

- 10mm single-sized drainage aggregate

- Backfill aggregate:

- Well-graded granular compactable material (recommended: 6I/6J), with a maximum of 15% clay

- Site-won backfill is acceptable if it meets the backfill criteria

- Geogrid:

- 35kN/m geogrid is suitable for most walls. A stronger geogrid may be required for certain surcharge conditions, slopes, or challenging soil types (such as 55kN/m or 80kN/m).

Selecting the correct geogrid strength based on the wall height, surcharge conditions and soil type is important. For most residential walls, 35kN/m geogrid is adequate. However, more challenging site conditions may require higher-strength geogrids.

Health and safety

The design of any retaining wall for residential projects requires input from an engineer to assess the unique site conditions, including loads and soil types. Proper site assessments and the appropriate wall design ensure safety during construction.

It is the contractor’s responsibility to ensure a site-specific health and safety risk assessment is completed prior to construction. Under the Construction, Design and Management Regulations 2015 (CDM 2015), designers and contractors must meet their obligations to ensure the safety of all workers on site.

Maintenance

SRWs are designed to require minimal maintenance. However, the following routine maintenance tasks are recommended for residential projects:

- Cleaning: Moss or dirt may accumulate on the block face over time. Cleaning can be done with moss cleaners/inhibitors if needed.

- Copings: Ensure the copings are fixed properly and check for loose or missing ones. If any are found, they should be reinstated with construction adhesive.

- Drainage: Ensure that the drainage pipe is not blocked. It is recommended to rod the drainage pipe annually to maintain proper drainage.

Certification

British Board of Agrément (BBA) certification ensures the SRW system complies with residential construction standards and is accepted by local authorities, building authorities and insurance companies.

Final thoughts

SRWs offer a versatile and efficient solution for housing developments, providing both functional benefits and aesthetic value. By carefully considering key factors during each stage of the process from design to construction, you can ensure that SRWs not only meet structural needs but also enhance the overall landscape.

As we have seen, SRWs are particularly well-suited for residential projects because of their adaptability to varying site conditions. Whether you are dealing with challenging slopes, poor soil or the need for a consistent finish across different areas, SRWs can be tailored to fit. Their modular nature makes them easy to install and maintain, and their durability ensures long-term stability.

When key considerations such as site assessments, material selection and proper safety measures are considered, SRWs can provide an appropriate solution for retaining walls in housing developments.

Please fill out the form below to complete the module and receive your certificate.

No comments yet